WITH THE MOST COMPREHENSIVE RANGE OF FUTURE HOME HEATING SYSTEMS IN THE UK

Thermal Earth has the expertise and knowledge to advise you on what heat pump system best fits you and your home on your journey away from fossil fuels. Since 2006 we've been designing and supplying high quality, renewable heating and cooling systems using ground source heat pumps, air source heat pumps, solar thermal and solar PV for projects of all sizes, from residential properties to industrial factories. Get in touch with us today for free, no obligation advice or to get a quote for your project.

The future of home heating systems - Heat Pumps

A heat pump is a magical device that extracts the heat from the air, water or ground and compresses it into a useable temperature to provide efficient comfortable heating and hot water to almost any building. We have extensive experience with over 3,000 completed systems since 2006 and know what it takes to design an efficient heat pump system that effectively heats any home and keeps running costs low.

UNBEATABLE KNOWLEDGE

With over 15 years experience in designing bespoke renewable systems.

SOLUTIONS FOR EVERY PROJECT

We offer a wide range of high-quality systems to suit all project types.

COMPLETELY ACCREDITED

We're also Trustmark accredited and members of the GSHPA association.

What are the different types of heat pumps?

There are three main types of heat pump: air source heat pumps, ground source heat pumps and water source heat pumps.

What are the running costs of a heat pump?

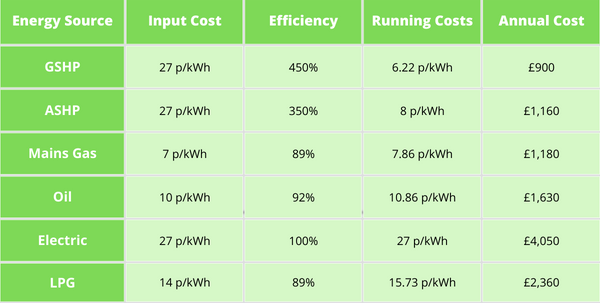

A Heat Pump is extremely efficient, especially when correctly designed. Meaning that a heat pump can save you money on your energy bills with low running costs over it's entire life span.

To give you an idea of it's efficiency a new gas boiler has an efficiency of around 90% whereas a heat pump has an efficiency of around 400%. This means that the energy you are using goes further, so you need less of it, which in turn reduces your monthly energy bills.

The table shows how the running costs of a heat pump compare to common fossil fuel alternatives.

*Please use this table as a guide as energy prices can vary. Correct as of April 2024. **Annual running cost prices are based on an average 4 bed detached house with an energy consumption of 25,000kWh per year

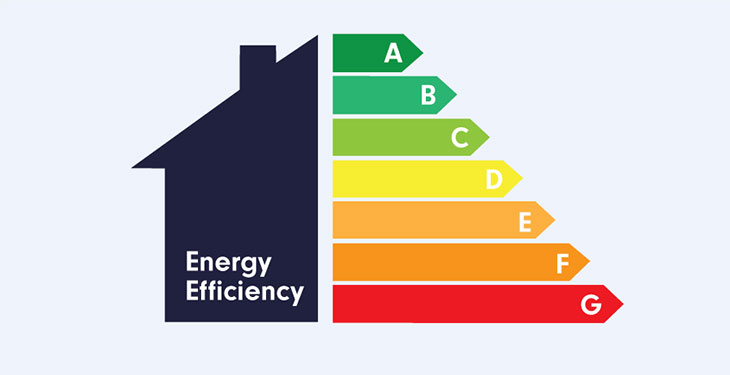

Is A Heat pump right for your home?

A heat pump offers a wide range of benefits, from reducing your carbon footprint to potentially saving money on energy bills. But how do you know if a heat pump is right for you? And which should you choose: air source or ground source? Complete our quiz to find out!

RENEWABLE ENERGY SYSTEMS

Thermal Earth are proud to offer the most comprehensive range of renewable energy services and products in the UK.

Solar thermal

Solar Thermal can provide as much as 70% of hot water requirements for a building.

ENERGY STORAGE

We’re official suppliers of Tesla PowerWall and Sunamp Thermal Energy batteries.

UNDERFLOOR HEATING

Maximise efficiency and comfort of your heating system with underfloor heating.

why choose thermal earth?

Our technical support team have worked extensively on developing our product offering from some of Europe’s top manufacturers. We offer over 2000 products (which we know inside out!) available to order online or by phone including heat pumps, solar PV, solar thermal, underfloor heating and storage batteries.

SMART SYSTEMS

MasterTherm heat pumps are compatible with the Agile Octopus tariff and will automatically self-optimise to achieve high efficiencies and up to 35% additional savings on your bills.

CASE STUDIES

Lappa Valley Visitor Centre

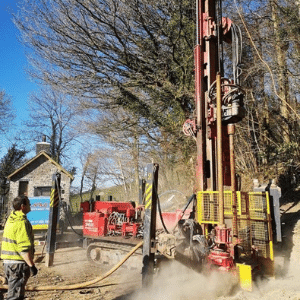

Installation of underfloor heating & ground source heat pump system in a café and play centre.

Lavender Farm Brecon

Installation of two ground source heat pumps for an office and residential property.

Start your thermal earth journey

Facebook

Facebook LinkedIn

LinkedIn Twitter

Twitter